-

Posts

5927 -

Joined

-

Last visited

-

Days Won

141

Content Type

Profiles

Forums

Events

Blogs

Everything posted by Splave

-

you can use a heatgun and bend it back no problem if it bends Also vivi has the right idea but I use scraper razor blades they have a blunt side. Seems better if you dont push hard just get the corners loose first then little by little on the sides. my 2 cents I have 25+ under my belt without death.

-

4x4 is better on Asus it seems, on ocf uneed to tighten the right mem timings

-

Splave.ROM - Core i7 6700K @ 6204MHz - 2081 marks XTU

Splave replied to 12's topic in Result Discussions

Thanks guys, very supportive bunch of people here appreciate it greatly -

Hazzan - Core i7 6700K @ 6190MHz - 2048 marks XTU

Splave replied to Achill3uS's topic in Result Discussions

Deserves respect -

Difficulty is only relative to the user. 32m is easy for me. Single card fse more difficult. More people benching 2d then award more points to 2d because there is more competition. VGA expenditures is causing a rift in 2d vs 3d. Also if you have deep pockets you can still bench air 4 way and get wr points no problem, how is that fair compared to someone working hard to push 2d on ln2. I think it's fine the way it is now.

-

Splave.ROM - Core i7 6700K @ 6400MHz - 7690.3 pps HWBOT Prime

Splave replied to Dancop's topic in Result Discussions

thanks men, BSOD on save file is soo funny can only laugh -

Bullant - Core i7 6700K @ 5650MHz - 1944 marks XTU

Splave replied to xxbassplayerxx's topic in Result Discussions

spot on good work -

goodnight sweet ddr3

- 489 replies

-

- skylake

- batch

-

(and 40 more)

Tagged with:

- skylake

- batch

- 6700k

- 6600k

- l510c971

- l510d077

- l512c763

- l514b860

- l519b740

- l519b743

- l519b744

- l519b875

- l519b892

- l519b932

- l519b972

- l519c078

- l519c087

- l519c193

- l520b668

- l520b669

- l520b990

- l520b994

- l520c033

- l521b643

- l523b383

- l523b475

- l523b667

- l524b278

- l524b329

- l524b520

- l524b542

- l524b663

- l525b503

- l525b504

- l525b530

- l525b538

- l525b711

- l526b243

- l526b394

- l527b204

- l527b622

- l527b662

-

SHIMIZU - Core i7 6700K @ 6409.3MHz - 7684.6 pps HWBOT Prime

Splave replied to Xtreme Addict's topic in Result Discussions

yellow efficiency! -

FUGGER - Core i7 6700K @ 6030MHz - 1968 marks XTU

Splave replied to hideo's topic in Result Discussions

more cache! keep going! -

Hazzan - Core i7 6700K @ 6100MHz - 2026 marks XTU

Splave replied to Leeghoofd's topic in Result Discussions

are you tired of the memory page of bios yet? haha -

Splave.ROM - Core i7 6700K @ 6100MHz - 2058 marks XTU

Splave replied to steponz's topic in Result Discussions

-

Xtreme Addict - Core i7 5930K @ 5760MHz - 2313 marks XTU

Splave posted a topic in Result Discussions

great job -

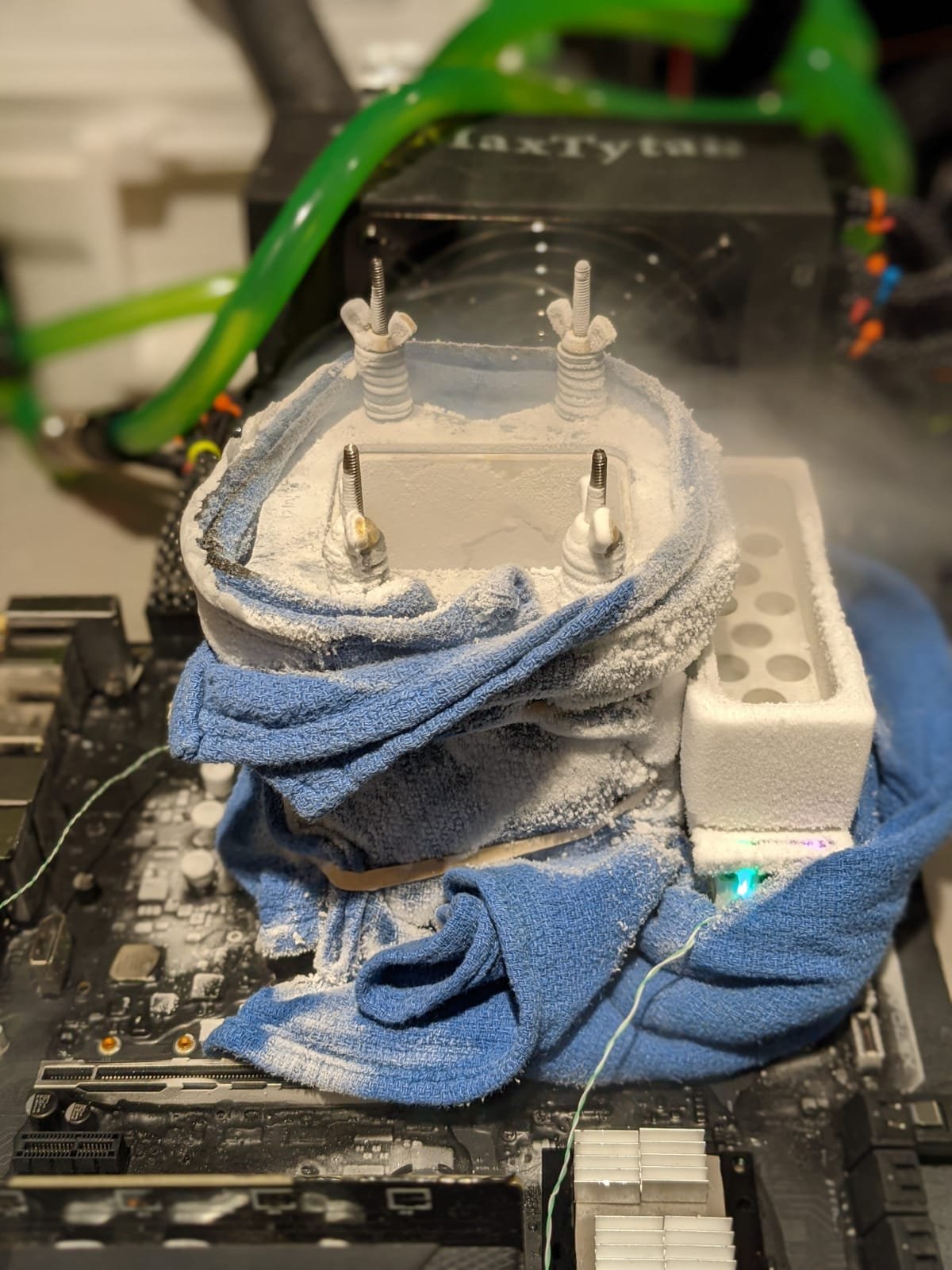

Its common knowledge skylake TIM is less than optimal, So I had some Indium Foil left over from some previous playing around.... INNNNDIUMMM, very heavy for just a small thin sheet. Its about 2-3 sheets of paper thick. Nice size piece over the die, it shrinks a little when it melts. Melting point is 157c so went well above that. "A rapid cool down is desired to form a fine grain structure. Slow cooling will form a large grain structure, which typically exhibits poor fatigue resistance. The acceptable cooling range is -0.5 to -6.0C/second (-2.0 to -6.0C/second is ideal)." Tried to maintain this using ln2 to cool it back down. Finished Product is nice and strong which is a good sign. :yepp: End Result, not great, not bad. 4ghz Core 1.35v through XTU on water cooling. Conclusion Will try a couple other ideas. Maybe the foil is to thin or too thick. Could stack 2 layers. Maybe my application is totally wrong. Either way hopefully indium company engineers respond to my email with some ideas. Keep thinking outside the box, one of these times its bound to be a home run.